One-way clutch

Also known as the power take-off (PTO) overrunning clutch, it is a safety mechanism used in agricultural machinery and other PTO-driven equipment. Its main function is to allow the shaft to rotate in one direction only, which protects the machine from damage caused by overload or sudden blocking.

How does the PTO overrunning clutch work?

Basic structure:

- PTO shaft: Transfers power from the tractor to the implement.

- One-way clutch: A mechanism on a shaft that allows rotation in one direction only.

Clutch operation:

- Normal operating conditions: During normal operation, the overrunning clutch allows power to be transmitted and the shaft to rotate in the direction that drives the work tool.

- Overload or blockage: When the work tool encounters an obstacle or becomes blocked, the overrunning clutch allows the drive to disengage in the opposite direction. This prevents excessive torque from damaging the mechanism.

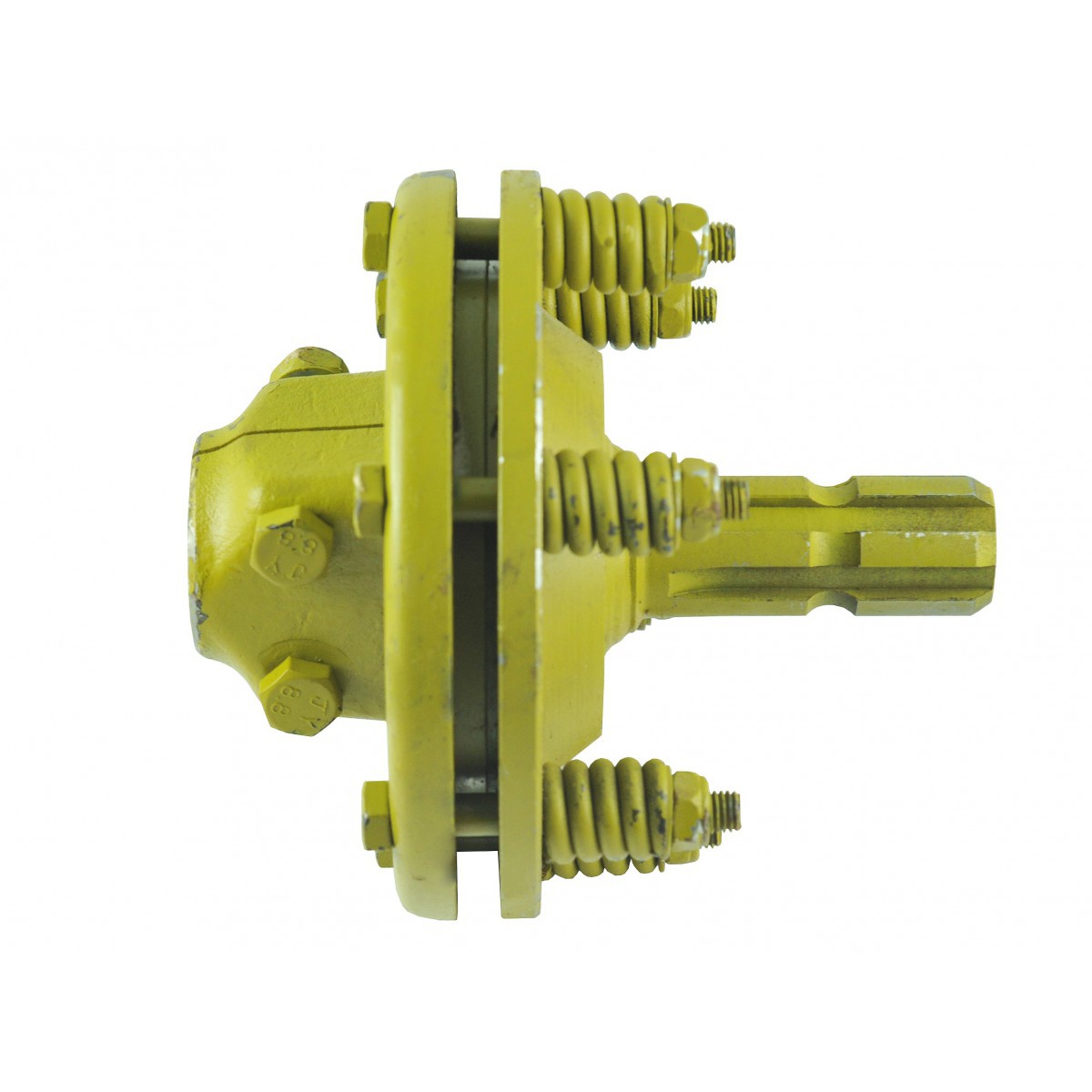

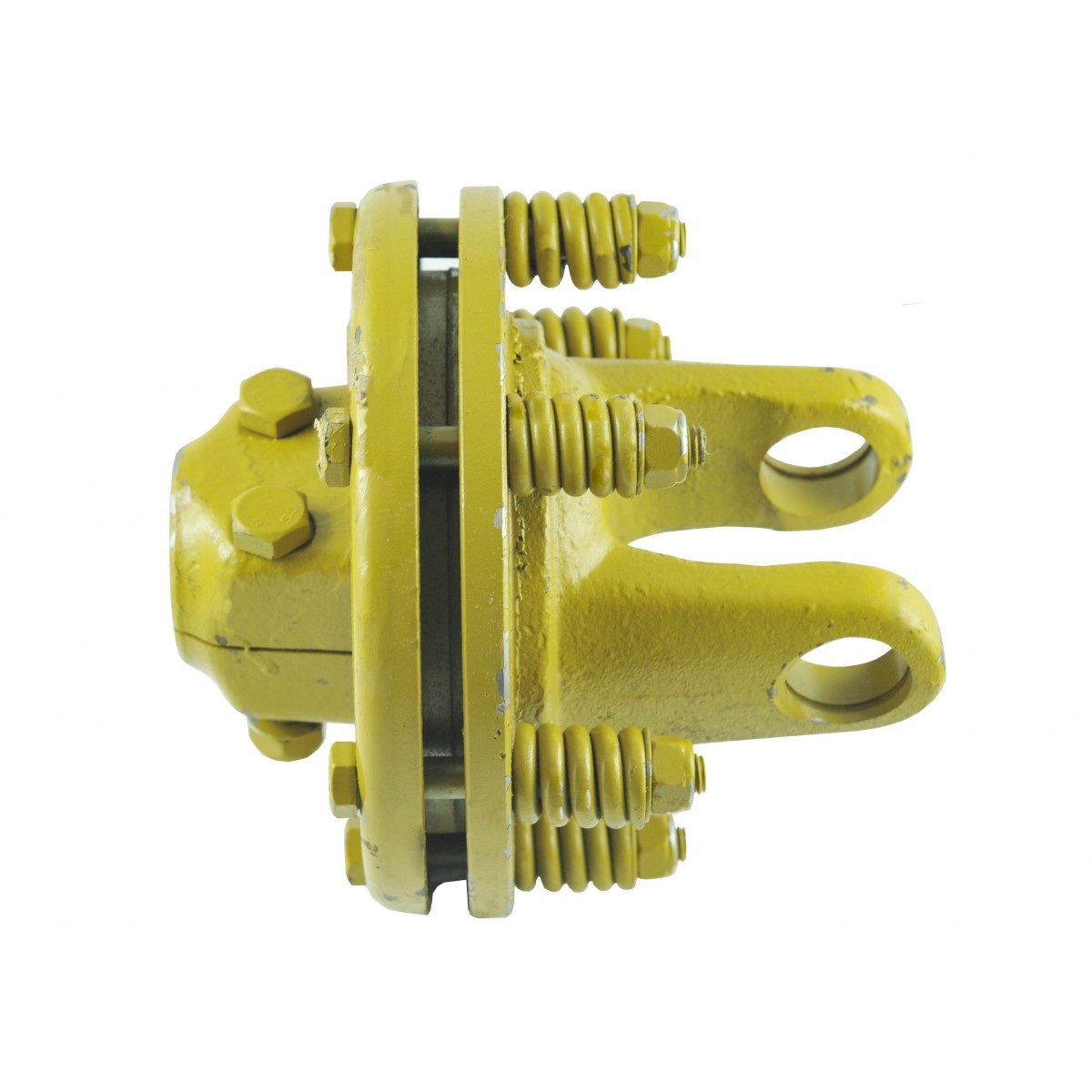

Friction clutch for the PTO shaft

This is a safety mechanism used in agricultural machinery. Its main purpose is to protect against overloads through controlled sliding of friction elements, which prevents damage to machines and the tractor.

How does the friction clutch for the PTO shaft work?

Basic structure:

- Friction discs: Consists of several discs made of friction material. They can be arranged alternately, one disc is connected to the drive shaft and the other to the driven shaft.

- Compression springs: Press the friction plates together to transmit torque.

Clutch operation:

- Normal operating conditions: Under normal operating conditions, the springs press the friction discs together with sufficient force to transfer torque from the tractor to the implement without slipping.

- Overload: When the work tool encounters a sudden load or blockage, the torque exceeds what the friction discs can transmit. Then the discs start to slip against each other, which reduces the transmitted torque and protects against damage to the mechanism.

PTO shaft reduction adapter

This is a device used in agricultural and gardening machines that allows you to connect the tractor's PTO shaft with a working tool with a different diameter or type of shaft end. These types of adapters are extremely useful when you need to use different machines with one tractor that has an incompatible PTO shaft.

How does the PTO shaft reduction adapter work?

Basic structure:

- Adapter input: An end that fits onto the tractor's PTO shaft.

- Adapter output: The tip that fits the work tool.

- Lock mechanism: Secures the adapter to the PTO shaft, preventing it from disconnecting during operation.

Adapter operation:

- Mounting the adapter: The adapter is mounted on the tractor's PTO shaft by inserting and locking the adapter input on the tractor shaft.

- Connecting the work tool: The work tool is then connected to the adapter output that fits into its shaft end.

- Power transfer: The adapter allows the transfer of torque from the tractor to the work tool, despite the difference in the diameter or type of shaft ends.