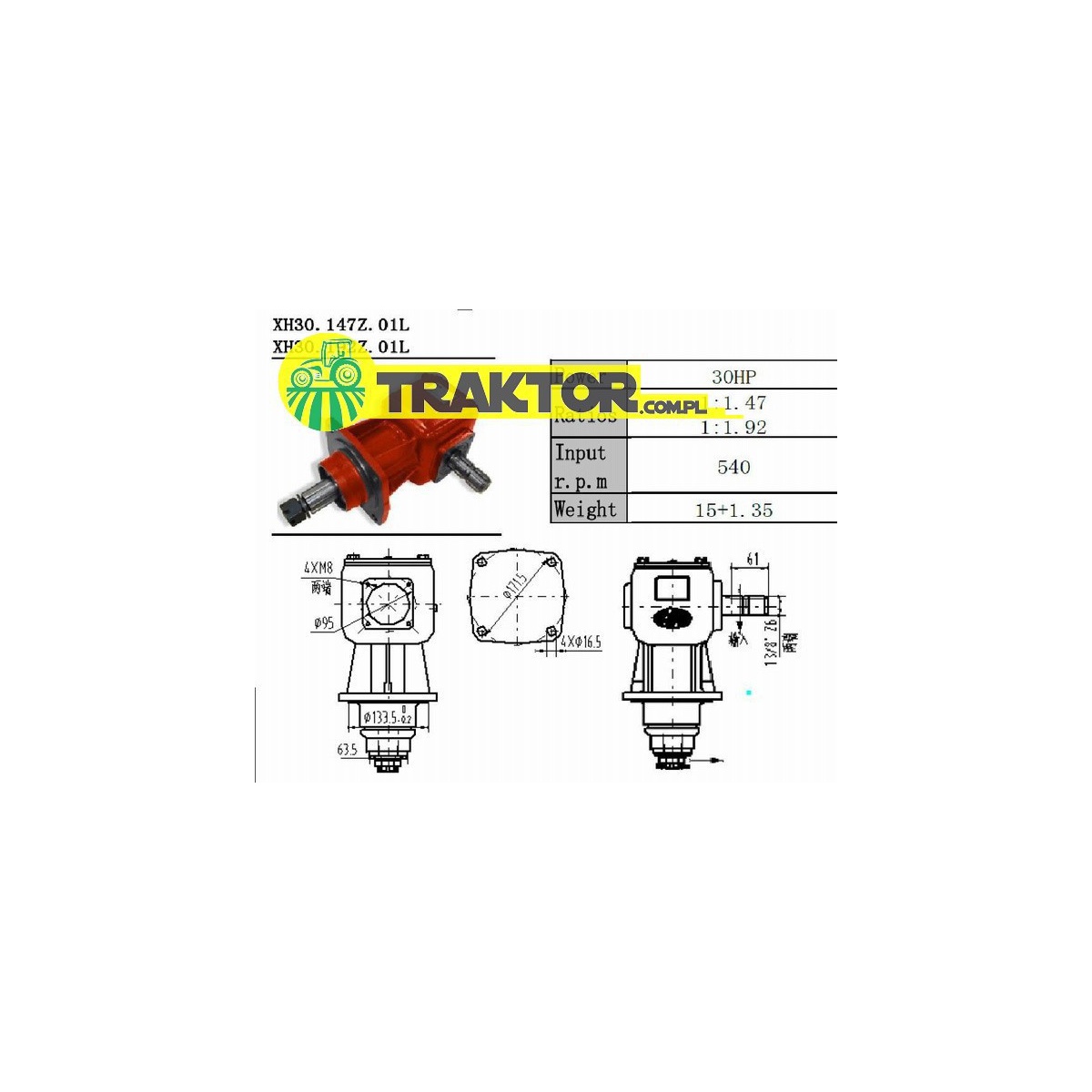

The angular gear in flail mowers plays a key role in transmitting power from the engine to the cutting knives or flails that are responsible for mowing the grass. This is an element that allows you to change the direction of rotation and adjust the rotation speed of knives or beaters to the working conditions.

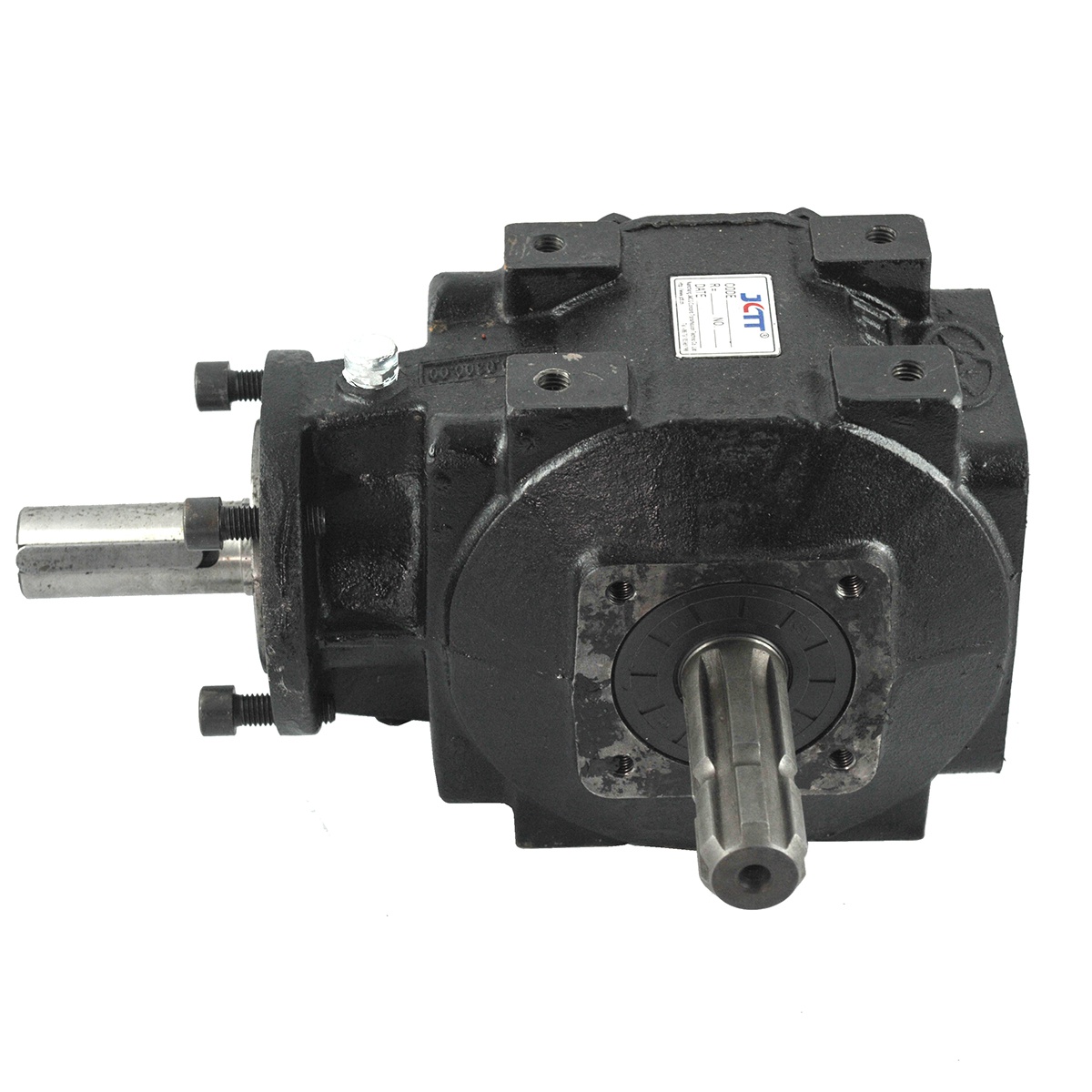

Construction of the angle gear in flail mowers:

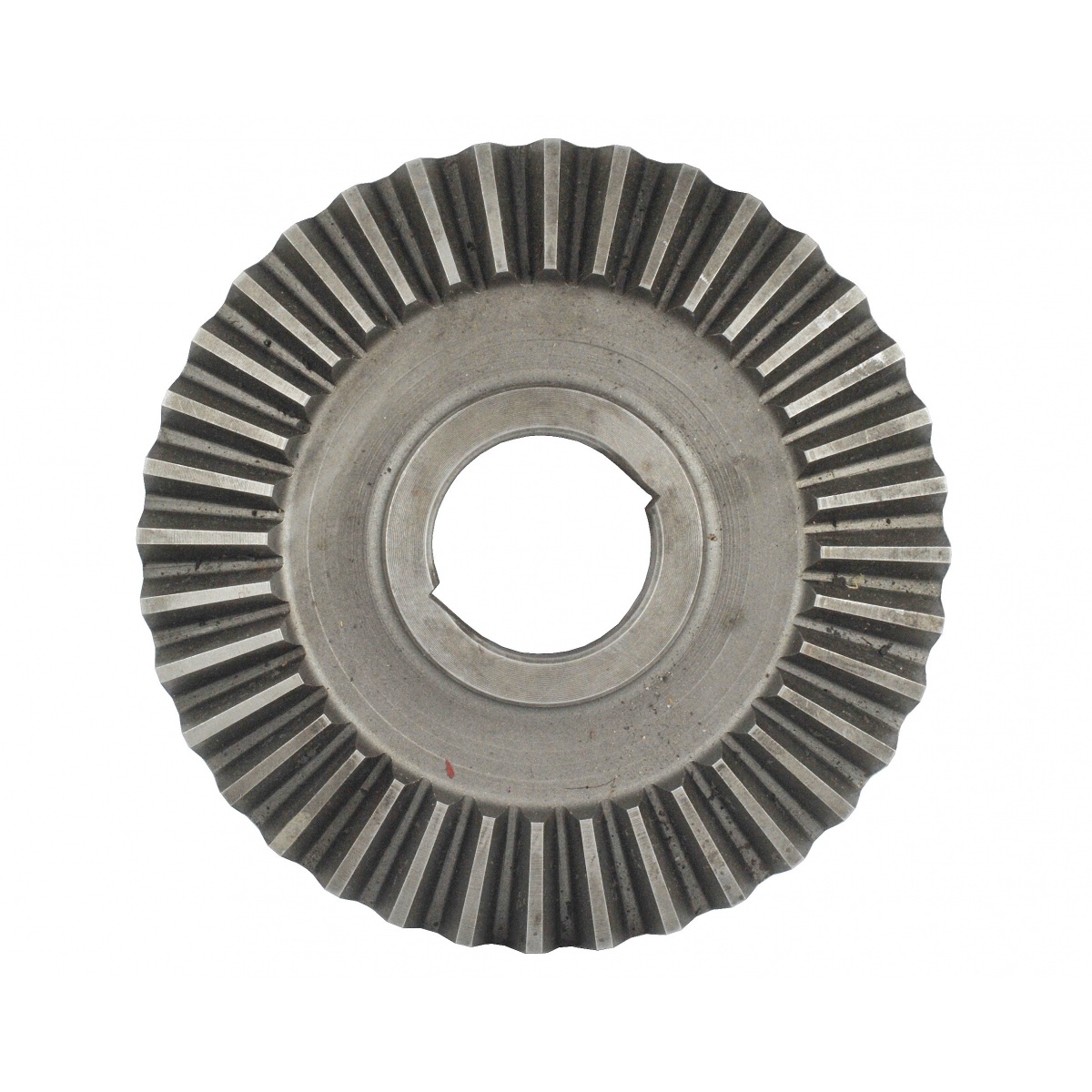

- Gears: The bevel gear in flail mowers most often uses gears to transfer power from the engine shaft to the blade or flail shaft.

- Gear Body: The gear body contains all the components such as shafts, bearings, and a housing that protects the interior from contamination and damage.

- Shafts and bearings: Shafts in a bevel gear drive transmit power between the gears, and bearings ensure smooth rotation of the shafts in the gear body.

- Housing: The housing protects the inside of the gearbox from external factors and keeps the lubricant inside.

Functions of the angle gear in flail mowers:

- Power transmission: The bevel gear transfers the power from the engine to the cutting knives or flails that cut the grass.

- Changing the direction of rotation: Changes the direction of rotation of the drive by 90 degrees, which is necessary for the proper operation of knives or flails in flail mowers.

- Rotation speed adjustment: In some models of flail mowers, the angle gear allows you to adjust the rotation speed of the blades or flails, which allows you to adapt to different mowing conditions.

Operation of the angle gear in flail mowers:

- Drive from engine: The mower engine transmits power to the bevel gear via a drive belt or direct shaft connection.

- Drive transmission: The angular gear transmits the drive to the knives or beaters shaft, which is responsible for the rotation of the knives or beaters.

- Adjustment and stabilization of work: Thanks to the angle gear, it is possible to precisely set and stabilize the operation of knives or flails, which ensures even mowing of the grass.